Black or Blue …WHY???

I have sometime get the questions about BL Silver Coat RT.

1When I coated Topclear it becomes black

2When I coated Topclear it becomes blue

In both it worked went through well up to Silver process. But it turns black or blue when on Topclear was on it. Today I will explain you that how to solve this problem and the mechanism.

It become Black

“I went through well all coating process with Silver. But I have a problem when I on the Topclear it turned dark…” I also had same situation many many time. There are several reasons why it happens.

Reason 2 : it was not enough heat to dry

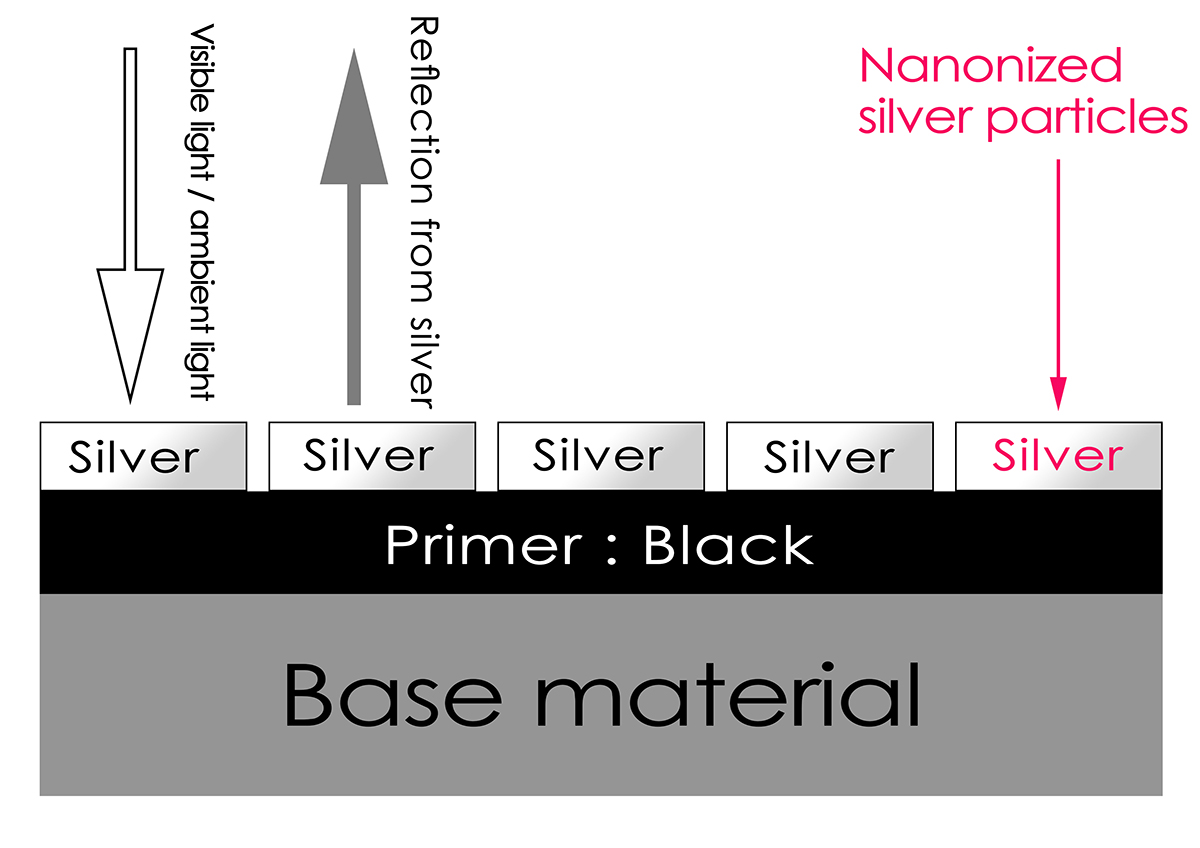

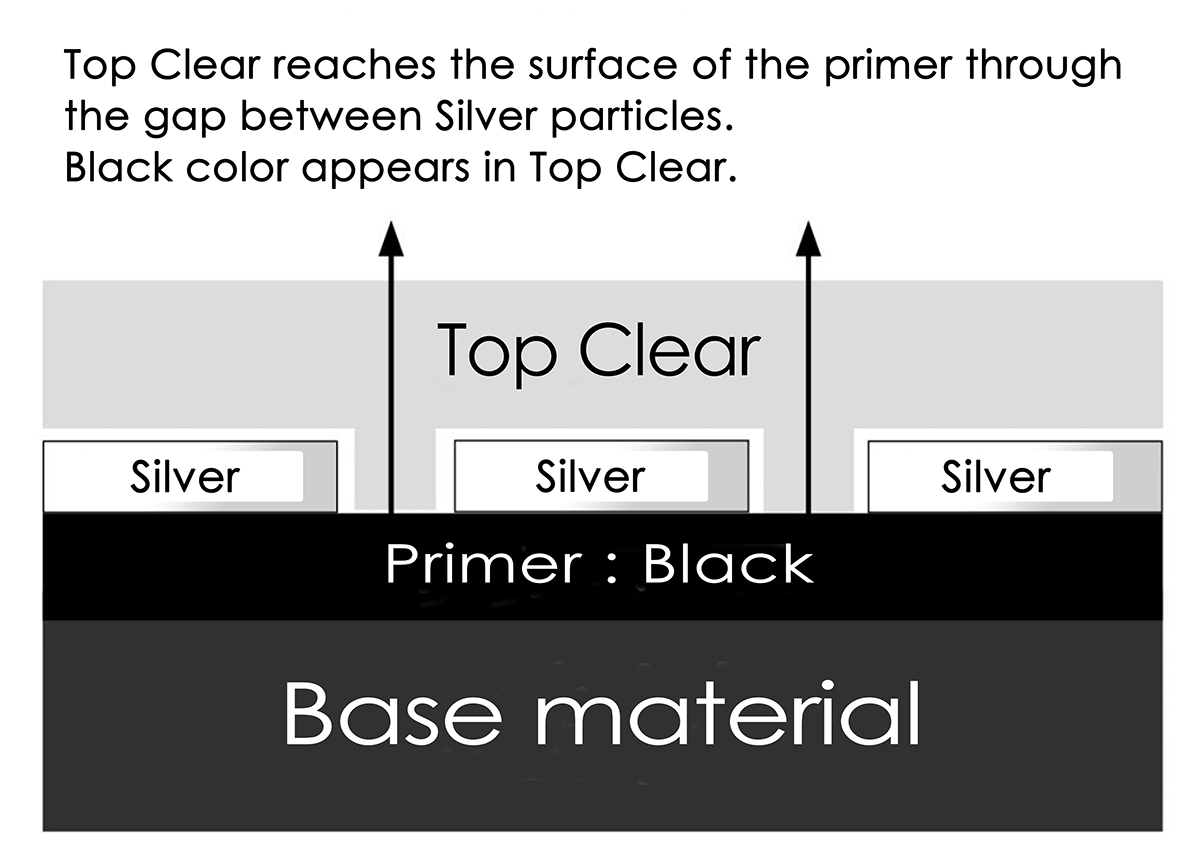

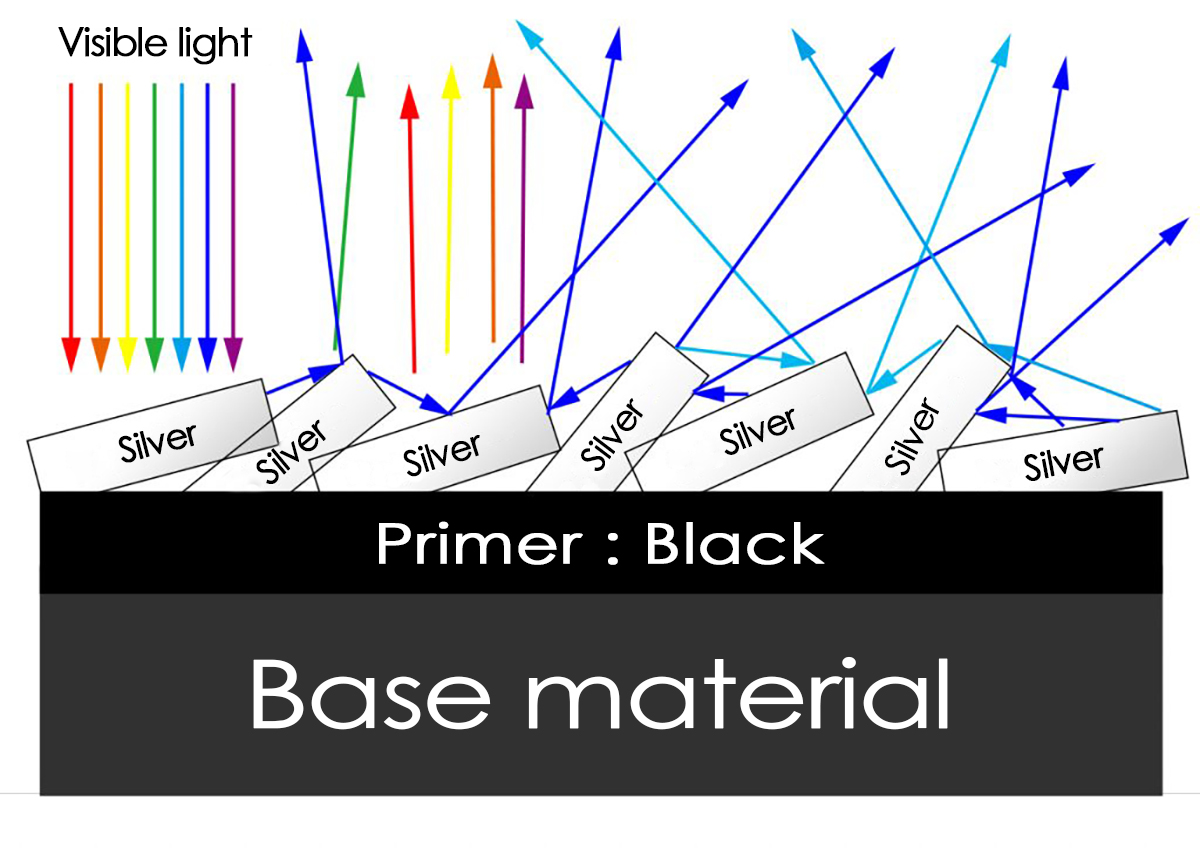

I described the mechanism of BL Silver Coat RT Please refer to picture below.

Black colour appears in topclear as you can see.

The reason of the above too thin silver layer it because black colour stand out visually. By the huge crevice between the silver particles then the black primer appeared. The other matter, it because is lack of drying. So silver colour wasn’t enough to shine but the Topclear was coated in the early stages.

It becomes blue

It is only one reason it could be the solving this problem so refer to my explain…

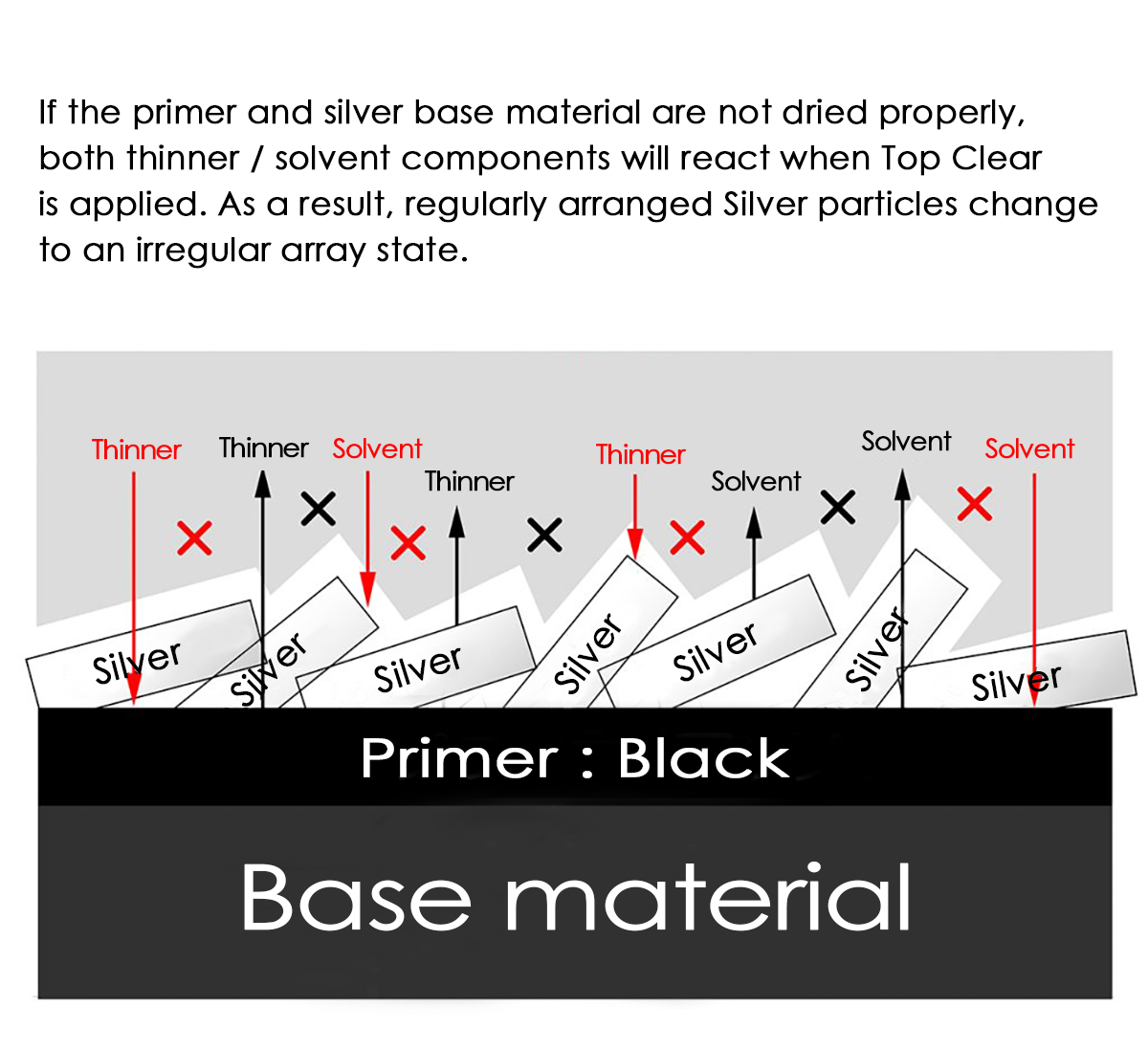

The thinner and another components remain on the primer but if already coated the Topclear so both going to react then it will change to irregular silver particles array. If the overlap and arrayed disturbed by external factor so it will change to another that emphasis the reflect of the blue wavelength in the visible light. The blue will appear br emphasised to the human eyes.

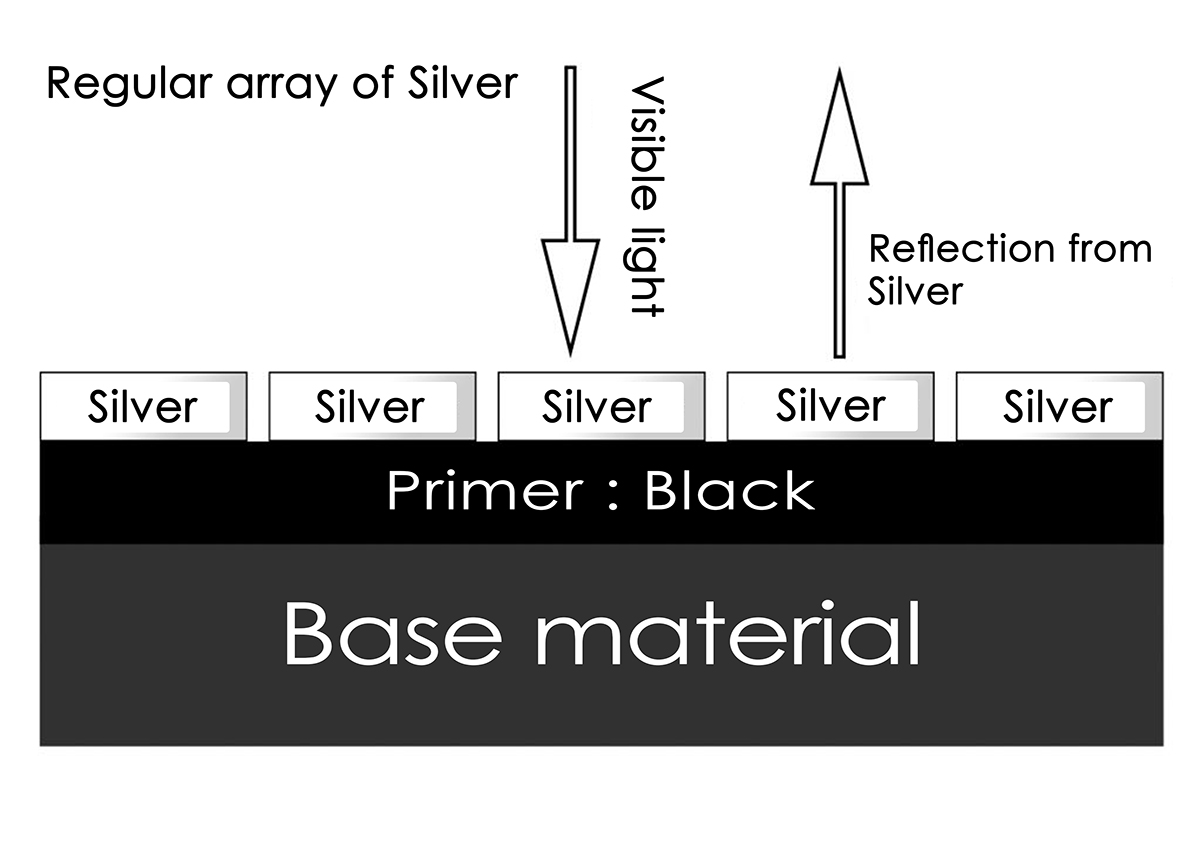

Mechanism : Silver arrayed particles uniformly

Countermeasures

Have you understood the reason why the silver surface turned black or blue after Topclear coated.

1Thorough drying after the primer

Forced air dry: 80-120℃( by material) 30-60min is standard

Normal temperature: Leave 7days more ( around 25℃)

2Perfect Silver coating

Since there are some tips for the silver coat the general countermeasures are described below. Please check the Silver coat original page for the detailed.

Spray gun set up

・Needle size : 0.8-1.3 mm

・Pattern : Full

・Discharge: 1-1/4 rotate back

・Air pressure: 0.2Mpa

・un distance: 15-20cm

Dilution ratio: Main Silver : Thinner=1:1.6

Main silver paint layer: 3-6 times

Forced air dry: 80-120℃/ around 20min

Normal temperature : Leave 7days more

The material can be withstand high heat, we recommend forced air drying at 120℃ at 20minutes.

BL HY-COATER

PRESENCE Co., Ltd. / BADLAND

4-18-1 Minamikase Saiwaiku Kawasaki Kanagawa JAPAN

ZIP CODE : 212-0055

TEL +81-44-587-3139 / FAX +81-44-580-3431 / info@badland.net

Comment On Facebook