Verification test the Top Clear Coat

Today I want to introduce you how excellent “BL Silver Coat RT” it is. I spent the almost 2018 full year at my paint section in my office because I focused on to build up my own cmethods for “BL Silver Coat RT” construction. During this work I tried some arrangement have my own way.

One of them is top clear. I mentioned my previous article that it never get nervous about appearance of the finishing the colour if it use after your constructed main silver agent drying enough high heat 120℃ around 20minute more dryer. It’s surface improving the texture never fails as like grows dark and more blackish.

Then I thought was it because it has not good quality the top clear coat is. Or it’s my own opinion. I didn’t believe that ability of top clear it self. I coated many various clear and glass coat to Silver main agent directly. How reckless I am without any proof and manual about coating process TRY and FAIL again and again. Looking back that was the turning point in my work. Nevertheless I achieved fantastic results as top clear coating. It looks incredible.

One is 250-2 our products / Sparkle Coat top Clear. Next is “Multi eco” by Nippon Paint 3:1 Clear. They keeps are stable condition as glossy and metallic Silver colour. This is found to have excellent affinity effects both are. I was so excited.

But if the surface look fabulous but how about ability? more over the most important thing is UV resistance.Who does know about it. So I might want to know the truth. I sent the 3 different painted bord off to our Research Centre once 2 weeks later I got received some results it was amazing…

[ Causion ]

Just noticed that adhesion test is only to be clear “ How about adhesion level this top clear when we coated to the silver mail agent directly “ these 2 Clear Coat is high quality it has nothing problem these casual tests like it.

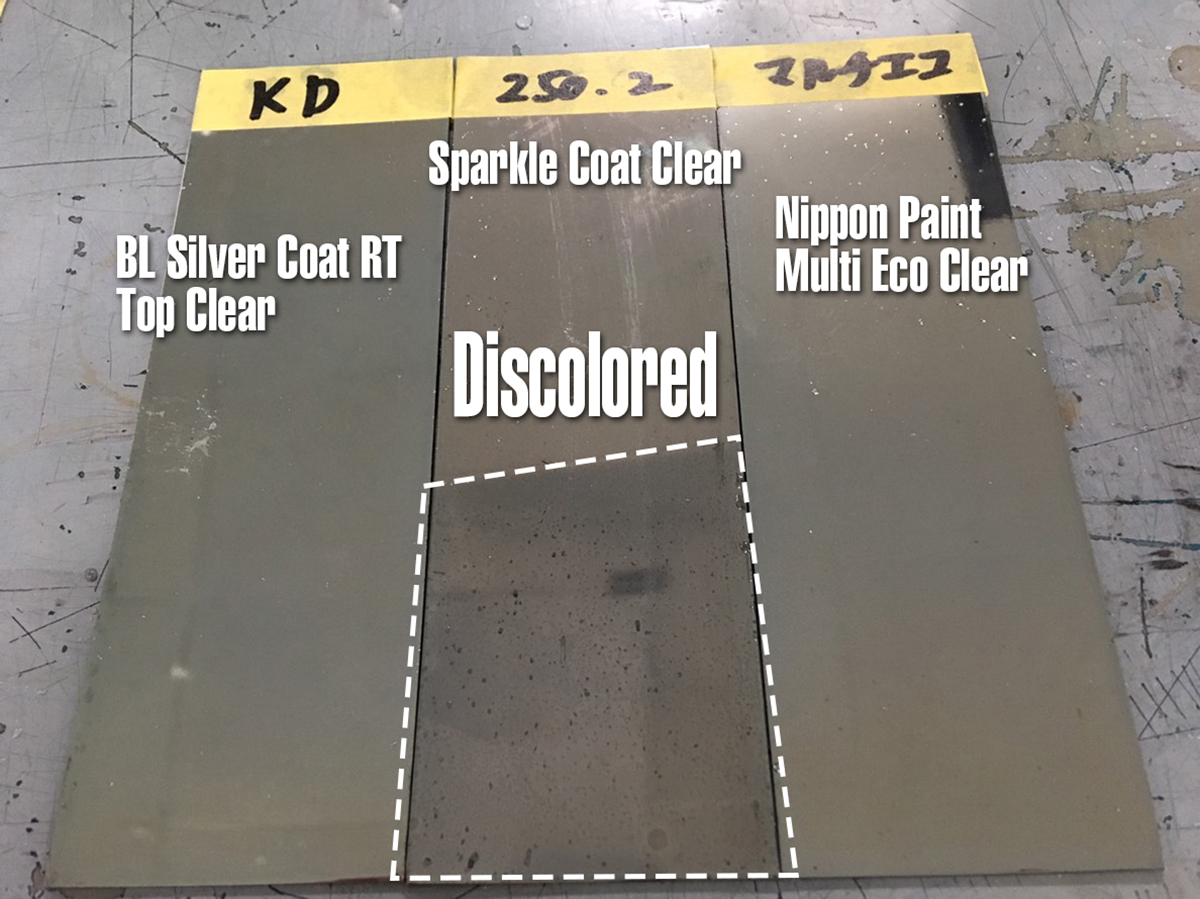

Water resistance test

Soaked the plate in 40℃ warm water for 4days.

250-2/ Sparkle Coat Clear : Discoloured

Multi eco: No discoloured

BL Silver Coat Top Clear: No discoloured

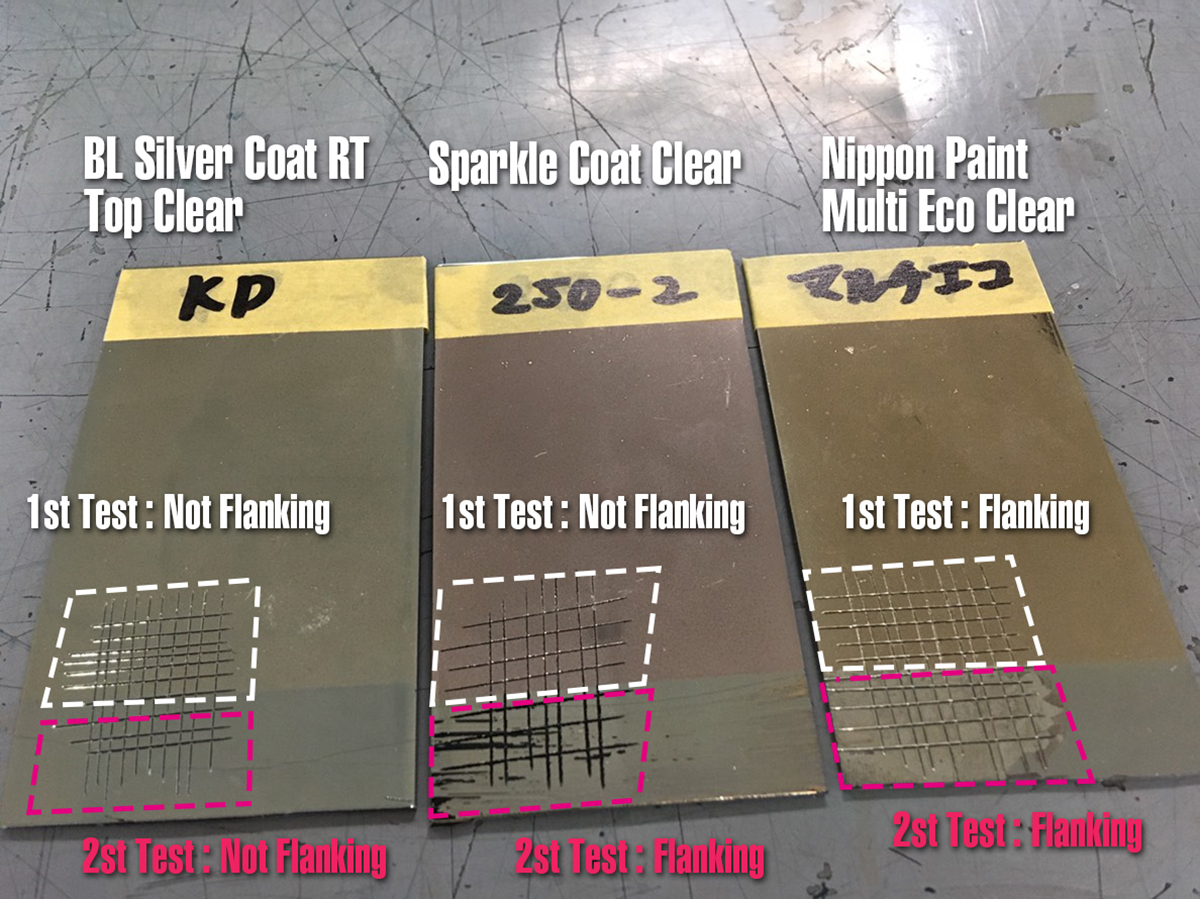

Adhesion test 1st and 2nd Test

[ 1st Test ]

Forced drying 30min at 80℃ dryer. Leave 6 hour in normal temperature.

There is provided 1mm crosscut tape test.

Multi eco : Flaking

250-2/ Sparkle Coat Clear : Not Flaking

BL Silver Coat : Not Flaking

[ 2nd Test ]

Soaked the plate in 40℃ warm water for 4days. There is provided 1mm crosscut tape test.

Multi eco : Flaking

250-2/ Sparkle Coat Clear : Flaking

BL Silver Coat Top Clear : Not Flaking

The one and only specialised BL Silver Coat RT Top Clear agent

As you can see from thecresults, that’s is just I was wrong doubting about “BL Silver Coat RT” top clear ability. And more it’a considering various situation which I thought was it sort of degrades for the R&D professionals to rolled out this top clear products…

After silver coated they must going into the dryer burning at 80℃-120℃ high heat once all the mixed substance or thinner composition removed. And then it looks very purely silver surface to show up. In addition these an adhesive coating agent against powerful enemy to an effects to UV resistance, weather resistance, and etc.etc. I was big mistake. I believed that I well known about Top Clear’s ability and quality but I had been questioning …

For now I loudly proclaim about this top Clear is one of specialised “BL Silver Coat RT”. This is the one and only very special top clear coating agent. I hope you do believe this Top Clear’s ability and opportunity and let’s moving forward to your construction!

If you have any questions and concerns. please feel free to contact us.

[ PRESENCE Co., Ltd. / BAD LAND ]

2-39-45 Shishigaya Tsurumi ku Yokohama Kanagawa JAPAN

〒230-0073

Tel +81-45-717-7026 / Fax +81-45-717-7027

e-mail : info@badland.net

Comment On Facebook