OSMO Stone Coat

OSMO Stone Coat is a special coating with penetrating performance that was especially developed for stone, concrete, and brick. It gives stone excellent water repellency, oil repellency, and dirt and stain resistance.

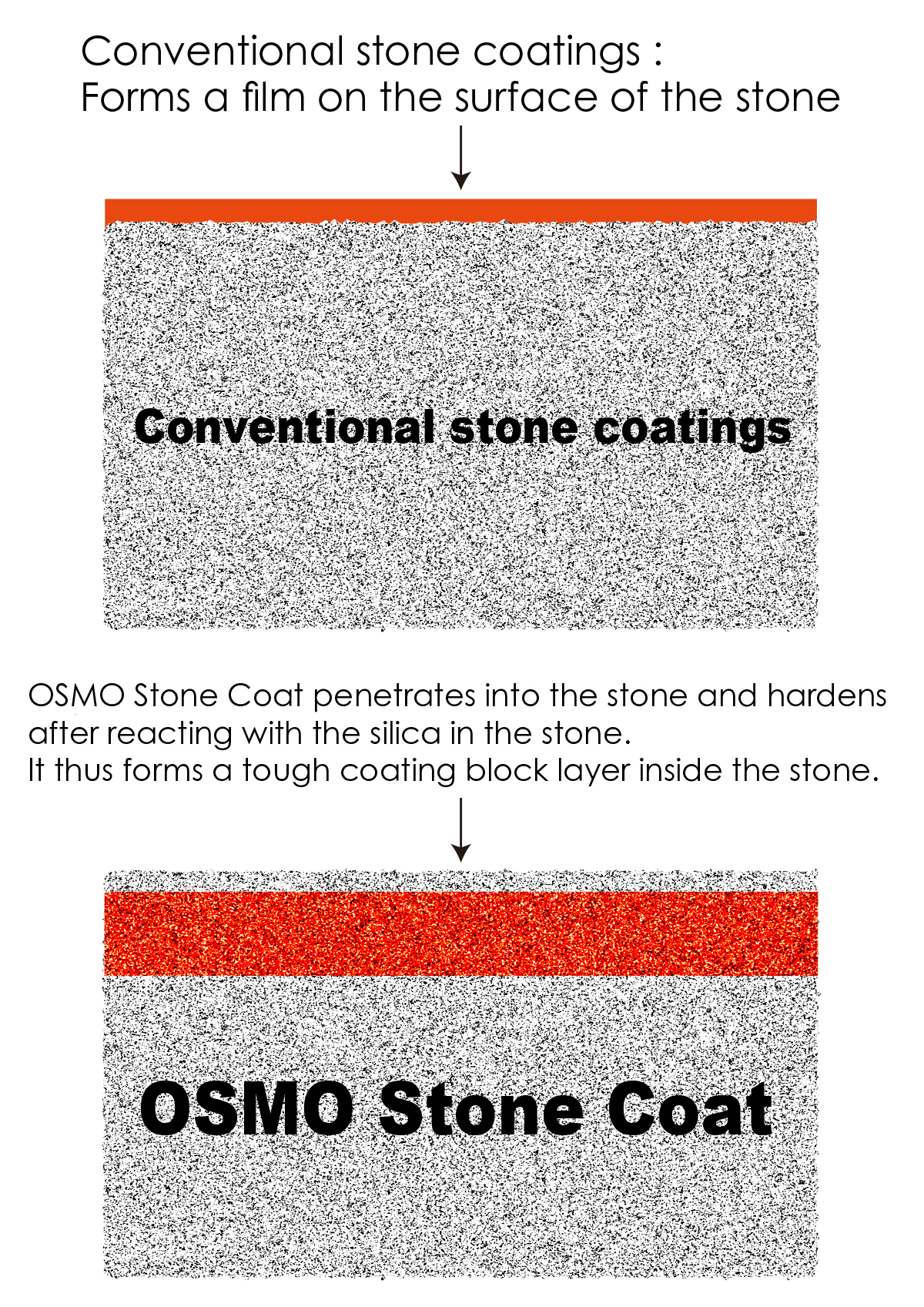

OSMO Stone Coat is a special coating that is blended with a special fluoropolymer to give it high penetration performance. After it is absorbed by the stone or concrete, it reacts with the silica in the stone and hardens. This forms an excellent coating block layer inside the stone with high water and oil repellency performance. This is completely different from conventional stone coatings that only form a coating layer on the surface. In other words, there is a physical action. For example, it will not be worn off and disappear in a short time by people’s shoes or car tires!

Characteristics

Tough water and oil repellency performance

It has excellent water and oil repellency and dirt and stain resistance.

Algae and mold prevention effect

It has excellent weather repellency and is effective against algae, mold, and efflorescence. Another characteristic is that it is very easy to peel off chewing gum, adhesive paper, etc.

Good texture after coating

The expression and texture of the surface is not lost after application.

Phenomenal long life effect

The weather repellency testing results were an amazing 8 years! Even under differing weather and usage conditions the durability performance is expected to last 3 to 5 years.

Water based for good workability

OSMO Stone Coat is a water based coating and thus has an environmentally friendly design.

Base materials that can be treated

Materials that can absorb water, such as stone, concrete, and brink.

For example, tombstones, outdoor structures made of stone (monuments, stairs, walls, stone walls, roads, etc.), train station platforms, toilet floors, exposed concrete walls and floors, marble floors and walls, etc., as well as the interior of tunnels, in other words, any material made of stone or concrete can be treated.

Application method

The coating is applied using a paint brush or roller. Spray guns can also be used.

The application method is really easy! It is just applied using a paint brush, roller, or spray gun. OSMO Stone Coat : Dilute with water 3 to 6 times the amount of coating. In addition, this is a water based coating, so it was designed to be very environmentally friendly. The water and oil repellency performance is realized several minutes after application. Further, there is almost no change to the texture after application.

OSMO Stone Coat : Standard coating conditions

Recommended dilution ratio / OSMO Stone Coat : Water = 1 : 6

OSMO Stone Coat is a water based special coating.

It can be diluted by adding an amount of water 3 to 6 times that of the coating.

To determine the dilution ratio, check the actual application conditions and adjust as necessary.

Standard application amount : 100 ± 30g /㎡

※ This depends on the nature of the application surface.

Drying: Approximately 30 minutes at room temperature

※ This depends on the weather conditions.

OSMO Stone Coat : Example application

To cover an area with length : 8m and width of a maximum of 3.5m, only about 75g of undiluted OSMO Stone Coat is required when applied to a stone floor. This is then diluted by 6 times more water. In other words, this entire surface can be treated with just 450g of solution.

OSMO Stone Coat Coating Precautions

Coating environment: Avoid use in environments with poor ventilation.

Preparation: Use a power wash or other means to sufficiently remove any oil, water, or dirt from the bare surface.

Use repair mortar to repair any chips or cracks in the base material ahead of time.

Coating: Make sure the surface to be coated is completely dry.

Drying: The water and oil repellency performance will occur several minutes after coating. This occurs especially quickly at warm temperatures and in good weather.

The reactivity is very weak for calcium carbonate based materials (lime, stucco, etc.), so it may take several days for sufficient performance to be realized.

Storage: Store the coating in a cool, dark location.

Handling precautions: Use large amounts of water to wash off any coating that comes into contact with the body.

Order

BL HY-COATER

PRESENCE Co., Ltd. / BADLAND

4-18-1 Minamikase Saiwaiku Kawasaki Kanagawa JAPAN

ZIP CODE : 212-0055

TEL +81-44-587-3139 / FAX +81-44-580-3431 / e-mail : info@badland.net

Comment On Facebook